- Advanced Manufacturing

- Biotechnology

- Business

- Communication, Social Sciences, Art & Humanities

- Construction & Maintenance

- Education

- Engineering

- Health Care & Wellness

- Hospitality & Personal Services

- Information & Digital Technology

- Public Safety

- Science & Math

- Transportation

- Propel

- Apprenticeships

- Non-degree Online Learning

- Adult Learners

- Entrepreneurship & Small Business Center

- En Español

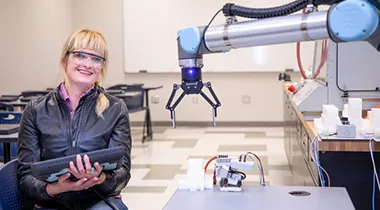

Wake Tech is dedicated to cultivating a skilled workforce for the manufacturing industry by establishing pathways for current and prospective workers to access opportunities in advanced manufacturing. Each training pathway is carefully designed to provide students with the skills required to excel in the technical and high-quality manufacturing jobs of the future.

The 3,000-square-foot Advanced Manufacturing Training Center serves the needs of area industry by providing workforce training in the following:

- Collaborative robotics – Robotics utilization, operation and basic programming

- Industrial automation – Automation systems, electrical, PLCs, hydraulics, pneumatics and mechanical systems

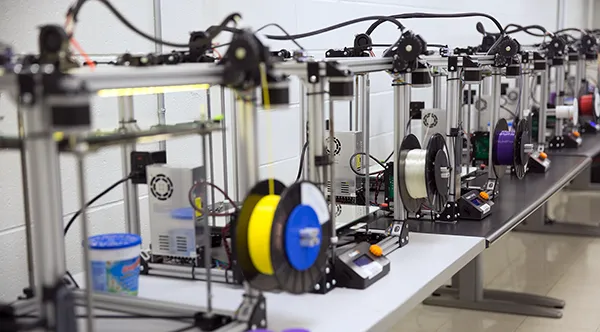

- Manufacturing – 3D printing, mechanical troubleshooting and mechanical blueprint reading

All programs include hands-on lab training supplemented with online instruction through Tooling University.

Come away with industry-recognized micro-credentials from the Smart Automation Certification Alliance and enhanced instruction from Tooling U-SME.

Faculty and staff

Chris Irwin

Program Director

~ Contact Info ~

William Burden

Advanced Manufacturing & Robotics Instructor

~ Contact Info ~

James "Steve" Evans

Advanced Manufacturing & Robotics Instructor

~ Contact Info ~

[email protected]

Beltline Education Center

Room 501E