Success Stories

A Maker Finds His Space

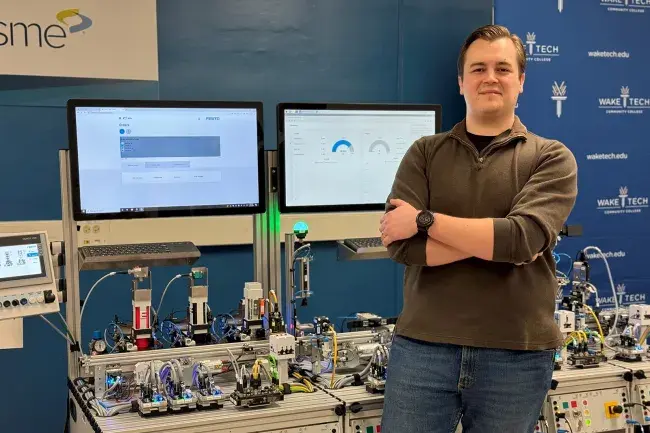

Karl Svoboda

Class of 2024

"There's always an opportunity to learn more here."

— Karl Svoboda

Karl Svoboda is a tinkerer. Working at a desk on a computer wasn't the life he wanted.

So, when he and his wife moved to Raleigh for her job a few years ago, Svoboda seized the opportunity and enrolled at Wake Tech to earn an Associate in Engineering degree.

The UNC-Charlotte graduate had spent a decade as an IT engineer at Magellan Aviation Group, a Charlotte-based firm that makes aircraft parts. While he enjoyed working in the aerospace industry and getting a feel for manufacturing, he says he wasn't satisfied managing the company's help desk.

"I want to make parts, get my hands dirty," he said.

Svoboda dove in at Wake Tech, looking for ways to get involved in what he calls "little projects." While taking a course in 3D printing, he met Brandon Audia, a lab technician for the Mechanical Engineering Technology program, who was laying the groundwork to open a makerspace for engineering students on Southern Wake Campus. Svoboda eagerly volunteered to help move an array of equipment – 3D printers, lathes, milling machines and more – into a space in Building F that formerly served as a training area for heavy equipment programs and to set it all up.

"This is a machine shop, basically," Svoboda said, adding that the makerspace "lessens the barrier of entry for engineering students" by providing access to an array of equipment where they can experiment and fine-tune class projects.

When Audia left Wake Tech early this year, Advanced Engineering and Manufacturing Technologies Department Head Al Brewer asked Svoboda to take over as lab technician.

"I needed someone to step up when Brandon Audia left mid-semester," said Brewer, who is now dean of the Engineering Technologies and Skilled Trades Division. "Karl trained the other student lab technicians and some of the faculty. Plus, he excelled in his role with supporting the makerspace, faculty and staff."

Svoboda says he enjoys helping other students in the makerspace and serving as its unofficial ambassador. He sometimes goes to classes to tell students what they can accomplish there, and he uses the 3D printers to create makerspace promotional items.

"I've been able to touch expensive equipment and not break it," he said with a laugh.

Steve Hudnut, director of the Mechanical Engineering Technology program, says Svoboda's intelligence and ability to reinvent himself for a second career are impressive.

"He's a superstar student, a super-fast learner," Hudnut said. "I can't say enough good things about the guy."

"He is driven to succeed," said Hessam Ghassemi, director of the Associate in Engineering program. "He's willing to dig deeper and learn more."

Svoboda is not only willing, he's doing just that. Associate degree in hand, he's continuing on at Wake Tech to pick up a welding certificate while also taking classes at Johnston Community College to earn a machining certificate.

"There's always an opportunity to learn more here," he said. "I was just going to finish my Associate in Engineering, but I kept looking for something to make me more valuable as a new hire."

Do you have a Wake Tech success story? Share it here.